Plastics injection molding involves injecting molten plastic into a metal tool, fostering efficient and cost-effective production of components. The process starts with melting plastic resin pellets, aided by cooling channels for solidification. Key components such as mold cavity and shot size influence the outcome. Heating initiates the plastic moulding process before injection into a mold cavity shapes the part. Cooling solidifies the plastic, resulting in the final part. Precision control is pivotal for quality outcomes. This guide covers the basics, process steps, popularities, methods, materials, and additives of plastics injection moulding, essential in modern industry.

Basics of Plastic Injection Moulding

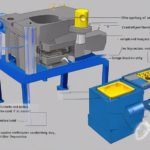

Plastic injection molding, a fundamental process in manufacturing, involves the precise injection of molten plastic into a meticulously designed metal tool to produce intricately detailed plastic components with exceptional accuracy. The plastic material, typically in the form of resin pellets, is first melted in a heated barrel before being injected into a mold cavity under pressure. Within the mold, cooling channels aid in the solidification of the molten plastic, allowing it to take the desired shape of the part being produced. Key components such as the mold cavity, shot size, and sprue are essential in guiding the injection molding process, determining the amount of plastic required and the entry point into the mold.

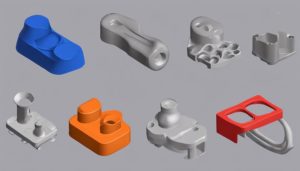

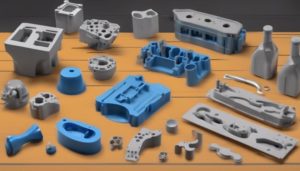

Plastic injection molding enables the efficient production of complex shapes and is widely utilized across various industries, including automotive, electronics, and medical devices. By understanding the basics of injection molding design and production processes, manufacturers can achieve high levels of precision and repeatability in creating plastic parts.

Plastic Moulding Process Steps

Initiating the plastic molding process involves meticulously heating plastic pellets until they reach a molten state within a specialized heated barrel. The molten plastic is then injected into a mold cavity under high pressure, where it takes the shape of the cavity. The cooling process is vital; rapid cooling allows the plastic to solidify quickly and retain the desired shape. The injection molding process steps typically include injection, dwelling to cool the plastic, and ejection of the final part. Precision control of variables such as temperature, pressure, and cooling times is essential to guarantee the production of accurate and consistent parts.

| Injection Molding Process Steps | |

|---|---|

| 1. Heating plastic pellets | Initiates |

| 2. Injecting into mold cavity | Shapes |

| 3. Cooling process | Solidifies |

| 4. Ejecting final part | Completes |

| 5. Precision control | Ensures quality |

Popularity of Injection Moulding

With injection molding accounting for over 80% of global plastic product manufacturing, its widespread adoption underscores the efficiency and precision this process offers in creating intricate shapes across various industries.

The high production efficiency of injection molding makes it a preferred choice for industries such as automotive, electronics, and medical devices where mass production of complex components is required. From small intricate parts to large components like car bumpers, injection molding proves versatile in meeting diverse manufacturing needs.

The cost-effectiveness of this method further solidifies its popularity, as it allows for the production of high-quality parts at competitive prices. The ability of injection molding to accommodate a wide range of materials and produce parts with minimal post-processing adds to its appeal in modern manufacturing.

As a cornerstone of plastic product manufacturing, injection molding's dominance is set to continue due to its ability to deliver quality, precision, and efficiency across various industrial sectors.

Types of Moulding Methods

Among the various methods employed in the manufacturing industry, different types of molding techniques are utilized to shape and form plastic materials into desired products. Injection molding involves using high pressure to inject molten plastic into a mold cavity, while compression molding uses heat and pressure to force material into a mold. Blow molding is used to create hollow plastic parts by inflating a heated plastic tube in a mold. Rotational molding rotates a mold around two axes to evenly distribute molten material, and thermoforming heats a plastic sheet until it's pliable, then molds it using vacuum or pressure.

| Molding Method | Description | Application |

|---|---|---|

| Injection molding | Uses high pressure to inject molten plastic into a mold cavity | Mass production |

| Compression molding | Involves forcing material into a mold cavity using heat and pressure | Automotive parts |

| Blow molding | Creates hollow plastic parts by inflating a heated plastic tube in a mold | Bottles and containers |

Materials and Additives Used

Utilizing a variety of plastic materials and additives is essential in the injection molding process to achieve desired product properties and characteristics. Injection molding materials commonly used include ABS, PET, polycarbonate, and polypropylene. These materials serve as the base resin into which various additives are incorporated to enhance specific properties.

Additives such as colorants, fillers, and reinforcements, such as short glass fibers, talc, and clay, are mixed with the plastic resin to improve attributes like strength, appearance, and heat resistance. Additionally, additives like UV stabilizers, flame retardants, and impact modifiers are employed to enhance performance in challenging environments.

Moreover, surface finishes play a crucial role in the final appearance of molded parts, with techniques like textured surfaces, pad printing, and laser engraving being utilized to provide aesthetic appeal and functionality to the end product. The careful selection and combination of plastic materials and additives are fundamental in achieving the desired quality and functionality in injection molded products.

Frequently Asked Questions

What Are the Basics of Plastic Injection Molding?

Plastic injection molding involves injecting molten plastic into a mold cavity to produce intricate plastic parts. The process commences with melting plastic resin pellets in a heated barrel for injection into the mold.

Cooling channels aid in solidifying the plastic material to the desired shape. Critical components like Shot Size and Sprue determine plastic quantity and entry point into the mold.

Injection molding machines vary in press tonnage, with horizontal and vertical presses offering different molding operation directions.

How Do I Get Started With Injection Molding?

To get started with injection molding, research and select a reputable company experienced in your industry. Understand design requirements, material selection, tolerances, and production volume needed.

Collaborate closely with the company to optimize part design for manufacturability. Familiarize yourself with the injection molding process steps like tooling fabrication, resin melting, injection, cooling, and ejection.

This approach guarantees a successful production run and cost-effective manufacturing solution.

What Are the 5 Steps of Injection Molding?

Injection molding consists of five critical steps: clamping, injection, dwelling, cooling, and ejection.

The clamping phase secures the mold, while injection involves filling the cavity with molten plastic.

Dwelling allows the material to cool and solidify, followed by the cooling step to harden the plastic further.

Finally, ejection removes the finished part from the mold.

These steps are essential for the successful production of plastic parts via injection molding.

Is Plastic Injection Molding Difficult?

Plastic injection molding can be considered a challenging manufacturing process due to its intricacies in mold design, material selection, and parameter control. The need for skilled engineers to manage factors like temperature, pressure, and cycle times underscores the complexity of this technique.

Despite its difficulties, plastic injection molding offers significant advantages in mass-producing high-quality plastic components when executed with expertise and proper equipment.

Conclusion

To sum up, plastics injection moulding is a widely used manufacturing process with various types of methods and materials.

One interesting statistic is that the global plastics injection moulding market size was valued at $258.2 billion in 2020 and is projected to reach $372.6 billion by 2028, growing at a CAGR of 4.6%.

This indicates the significant growth and importance of plastics injection moulding in the manufacturing industry.