Introduction

However, the costs of these benefits are far too damaging to our environment. There is overwhelming evidence that the costs of plastic are very high. The cheap and versatile nature of the material has led to it being used in an incredibly wasteful manner. Many plastic products are used only once and then discarded. This increase in the use of disposable plastic is mirrored by the increase in plastic waste in our oceans and our lands. The damage to the environment and also the amount of resources being utilized adds to the negative impact of plastic and what it is and what it has become today. From an environmental perspective, it is a disaster.

Plastic is an essential component of our day to day lives. It is used in areas like manufacturing, packaging, and human contact. It was meant to be a revolutionary product in the early 1900s at the turn of the century. It was said to be versatile, durable, and also cheap to produce. It certainly did live up to all those expectations. It has revolutionized the world so much that it now has been labeled as a “throw away” culture. There is no denying the benefits of plastic. They are so many. End products are lighter, cheaper, and more functional and pragmatic.

1.1 Importance of plastic recycling

Although these costs may humor much of the public as a significant issue in today’s society, many would argue that the reserves of oil are more of a concern. Because plastic is made from oil, and oil is a finite commodity, there will come a time where plastic production will no longer be viable due to rising costs. This again can have many effects on global society. The remaining oil would be of more economic value to keep for energy production and transportation fuels, rather than using it for more materials. This will mean a massive change in the material that plastics are made of. Other materials require a more complicated life cycle and may incur even greater costs to the environment and society than plastics have today. And although there may still be some petroleum-based products being made from the remaining oil, these will likely be much more expensive than what we are using today. This will all have a knock-on effect on the consumer of these products, who could be less inclined to buy a more expensive plastic that is no longer the convenient choice that it is today. And thus, an age without plastics may have its plethora of positive effects on the environment, with the assumption that it is managed correctly.

The more obvious cost is the cost to our environment. When in landfills, plastic can take up to a thousand years to decompose, and in doing so, can leach toxic chemicals into the water and soil, and release greenhouse gases in the process. When in the environment, plastic waste can do even more harm. It is thought that 80% of all litter in the ocean is land-based, of which plastic comprises the largest. One way or another, this debris can make its way back into human consumable resources when aquatic life mistakes it for food or has it fed to them as part of the fishing industry. This can also directly affect the lifestyle of regional communities living near coastal areas.

Plastic pollution has the potential to be a major cost for future generations, not only in economic terms but also in terms of public health. Every bit of plastic that has been created is contaminated with some kind of toxic or poisonous substance. These can affect even future generations who have come into contact with the plastic. Apart from that, much of this toxic chemical is actually transferred to animal tissue that has consumed the material. In this respect, plastic waste can also be seen as a threat to biodiversity and the stability of ecosystems. It is understood that due to the durability of the polymer, this in-depth effect may need thousands of years to recover from as well.

1.2 Growing concern for plastic waste

The mid-20th century came with a revolution in the manufacturing industry, filling shelves and businesses with plastic. From empty ketchup bottles to taking out the trash, the effects of this revolution are apparent. Initially, it propelled convenience and waste management as household bounties, but a growing concern of plastic waste is now evident. In part one of this resource, the historian talks about the remarkable growth of the plastic industry and perceives that the material has transformed too rapidly for consumers to consider the consequences. This transformation has led to limited durability of disposable plastic products, to an extent now where the detrimental effects of plastic in the environment can take centuries to reverse. Carey comments about the complexity of plastic as a material, suggesting that its different forms offer a variety of uses, but in most cases, the cost is greater as a pollutant. Clement and Lindner’s article mentions that the life cycle of a plastic product is relatively short and because efficient waste management has not been put into place, there has been a rapid accumulation of plastic in municipal waste and landfills. With an estimated 10% annual increase in this figure, it can be argued that the prosperity of the plastic industry has come with a long-term burden from its consumers.

2. Plastic recycling machine: An overview

Plastic recycling machines are any technology that can be used to reprocess plastic waste, often incorporating various techniques to produce a useful final product. The many processes used in the recycling of plastics are constantly being improved upon and adjusted to make better quality reclaimed material. These sorts of changes will also lead to a reduction in the waste generated, that is, the production offcuts and waste plastic from factories. This is the result of more efficient ways of recycling, thus improving the economics of recycling and therefore the viability of reprocessing plant and a decrease in landfill or incineration of plastic waste. Most recycling of post consumer waste is currently done for different forms of PET. Bottle-to-bottle recycling is thus quite important in the recyclate industry. An efficient method of doing this is process of wet granulation, where the glue used in the paper labels on the bottles is separated from the PET, maximizing re-processability of the reclaimed material. New developments on the PET recycling process are also being made through the various research institutions based in Japan, often in conjunction with machinery manufacturers. The plastic material is recycled to create other items, an example of the reprocessed material is extruded into pipe profile, this material is recycled using a machine called a profile extrusion line. Plastic recycling machines range in size, rigidity, and general complexity, from basic knife granulators and pulverizers, to high-speed friction washers with a long water prewash, and varying systems of sopping the warmed and friction-activated waste. Because of the many complexities and variations in recycling systems, often manufacturers will carry out trials on the customer’s materials to ensure the best possible recycling system. This often involves consultancy from the recycling machinery manufacturer, a valuable service for the consumer. It has been known in some cases that the manufacturer has set up a recycling line in his own factory to process the customer’s plastic waste, in order to prove the applicability of the system.

2.1 Types of plastic recycling machines

Pelletization machine directly processes the cleaned plastic through a heating process and then into a small mold that will shape the plastic into small pellets. Both of these types of machines have their own advantages and shortcomings compared to the other, thus it is important for the manufacturer to be able to identify the right type of machine that is suitable for their production line. Or in certain cases, a combination of both types of machines would be the ideal solution.

Extrusion type recycling machines use a hot mixer which contains a screw that will compress and transport the melted plastic into another washing and drying machine to clean the plastic further. Then, the plastic will be conveyed to an extrusion machine. Grooves on the machine transfer heat to the plastic until it is melted. The plastic is then forced through a die and comes out in the form of long strips, called extrudates. These extrudates can be cut using a high-speed pelletizer to make pellets of uniform length, which are easier to handle than extrudates.

We can categorize the types of plastic recycling machines based on the methodology that is employed to process the wasted plastic. The following, we will discuss the 2 main types of recycling machine that are commonly in use: extrusion and pelletization (Masternak, 2004).

2.2 Working principles of plastic recycling machines

The working principles of plastic recycling machines follow a general sequence. Firstly, the waste plastics are loaded into a sealing off the equipment. These can be stiff or shredded. An extrusion machine, a recent type of machine, applies only to certain types of plastic such as PVC. More details on this type of machine are provided below. It acts as a giant pasta maker. The system heats the plastic in a continuous flow process, as opposed to melting and reforming the material. The heated plastic is pushed through a mechanism, which should be a die, to produce a specific shape that depends on the type of the machine. The machine, an autoclave recycling of HDPE type 2, coded plastics, uses a batch process which has a sequence of stages: 1. Fill 2. Heat 3. Apply force for compaction 4. Cool 5. Eject.

2.3 Advantages of using plastic recycling machines

The waste is now starting to leave the environment as a concern for future generations, and it is time to turn it into a valuable item. Compared to other materials like metals and wood, the recycling rate for plastics is relatively low due to its low value. Generally, it requires an efficient method and consumer participation to increase the plastic recycling rate instead of using it for landfilling and incineration.

The amount of plastic waste is growing every year and nobody knows what to do. But in this paper, we are going to discuss the solution to plastic waste with a developed machine. Although initial analysis may suggest an absence of waste plastic, in reality, it is calculated to be 8 million tons per year, coming from various sources.

The variety and aroma of plastic bags have made their utilization one of the most frequent items in the world. They tend to be low-cost, lightweight, and resistant to water, used in millions of tons per annum. They pose a great threat to the environment.

3. Impact on waste management

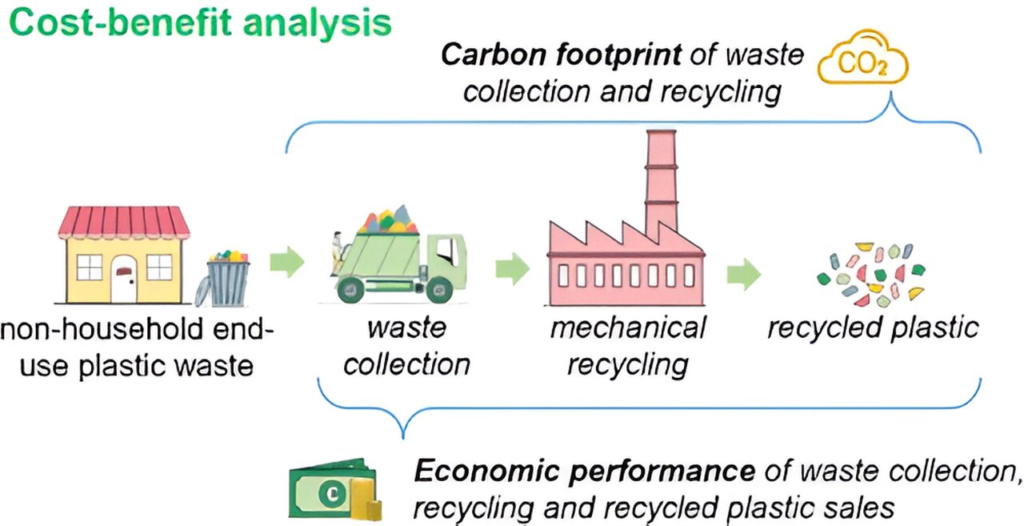

Recycling is also said to be the best solution for waste management as it is environmentally friendly compared to incineration and landfilling. Plastic recycling machines promote the circular economy. This is due to the fact that they allow the plastic to be broken down and reprocessed into new materials instead of pushing the same materials toward incineration or landfill. This ultimately reduces the usage of raw materials to produce new plastics and provides a better alternative to incorporate recycling.

Recycling plastic using recycling machines improves the economy and saves a ton of money on waste disposal, which is a major issue of concern for local or city councils. According to a case study done in New Zealand, the implementation of plastic recycling machines had the potential to save NZ $51 million over the next 20 years by diverting plastics from landfills.

The implementation of plastic recycling machines would lead to a significant reduction in waste sent to landfills. Shredded or crushed plastics can be used as materials to manufacture other plastic products, reducing the volume of waste. This would reduce the usage of landfills and help to reduce landfill costs, relieving the pressure to find more landfill space.

Plastic recycling machines greatly impact and benefit waste management in various ways, as explained below.

3.1 Reducing landfill waste

There are two ways of reducing waste in landfills: either reducing the amount of material going to landfills or increasing the amount of waste diverted from landfills. The implementation of plastic recycling machines is considered as a method for the latter. Plastics recovered from households go to the materials recovery facilities (MRFs) with a mixed range of different types of plastics. Usually, a significant proportion will further be sent to landfill. With the implementation of the recycling machines, more of the plastics going through the MRFs will be recycled, reducing the amount of plastics going to landfill. The machines could therefore be a tool for reducing the amount of waste going to landfills. Plastics can be difficult to recycle through traditional recycling methods, and often the quality of plastic degrades every time it is recycled. Plastics sent to landfill can be used as an alternative fuel source for incineration, potentially leading to less environmental impact than recycling. However, often plastics in landfills are considered as a long-term and temporary carbon sink and can release greenhouse gases into the atmosphere. This can occur from the degradation of landfilled plastic into microplastics and methane release from any anaerobic decomposition of organic material around the plastic. Substituting the incineration of plastics for energy with the recycling of plastics may take time, but would lead to a reduction in greenhouse gases if fewer plastics were present in landfills.

3.2 Promoting a circular economy

The plastic recycling machine promotes a circular economy in which the resources, energy use, and waste generation are minimized. In the conventional linear economy, natural resources are taken from the earth, used to create products, and then disposed of as waste. A circular economy involves taking those items and reintroducing them into the system to be reused or recreated. This is a crucial concept when analyzing plastic recycling technology because it changes the way plastic is used and disposed of. In a circular economy, plastic is not thrown into landfills or incinerated; instead, it is seen as a valuable resource and used as feedstock for manufacturing new products. By doing so, it can improve energy efficiency and security in the plastic industry, create new jobs, and stimulate innovation in sustainable technology. The recycling machine ensures low waste generation. Since the plastic recycling machine can process all types of plastic moldings, parts, film, and products, it saves a large amount of waste compared to conventional disposal methods. Some recycling processes can even produce recycled products in the form of pellets. An example of waste reduction can be seen in the UK, where WRAP (Waste and Resources Action Program) claims that recycling 1 tonne of PET bottles saves 1.5 tonnes of carbon emissions. This is based on the PET being processed into new bottles and used as a 25% blend with new PET. With approximately 1.8 million tonnes of plastic packaging consumed in UK homes in 2009, the potential waste and energy savings are considerable.

3.3 Challenges in implementing plastic recycling machines

A key challenge in implementing plastic recycling machines is that plastic is incredibly diverse, from the basic chemistry of polymer formulations, as well as the broad spectrum of additives used throughout the manufacturing process, to the multiple forms of the resultant packaging or products. This makes it extremely difficult to attain the quality of sorted material that is required to satisfy the end user in terms of matching color and additives attributes in particular. It is important to understand that the ISO standards for these contaminants in the plastic packaging recycling stream only provide a specification and do not restrict the level of contamination. Additives in plastics that have been highlighted as potentially toxic or hazardous are anti-static agents, flame retardants, and colorants. Another challenge is that of an economic one. The potential for health and environmental damage imposed by the waste materials on the wider community needs to be internalized into the cost of current disposal methods. With landfill costs being quite low, this makes the competitive use of recycling machines an uphill battle. Often in the case of injection molding businesses that generate offcuts and faulty products, it is more efficient to reuse this type of material internally, considering the volume and value of on-site plastic granulate is known and can be used as a cost-effective material. The result of this is a reduced supply of clean recyclable materials to the open market. Often there can also be a steady relationship with an existing waste disposal company that possesses in their eyes a tried and proven waste management system. Changing to another method can be seen as too great a risk and potentially higher costs.

4. Future prospects and innovations

Plastic recycling has come a long way over the years, however there is still a long way to go. There are still many problems associated with plastic recycling such as the high cost of recycling and the lack of materials that can be recycled. On the economic side of this issue, the cost of producing plastic from raw materials is much cheaper than from recycling (Plastic Recycling, 2008). In the past, the plastic industry has used ‘virgin material’ to manufacture products because it has been cheaper than using recycled material. Virgin material is the term used for newly refined material. Due to the increased cost of recycling and the inability for recycled plastic to compete with virgin material, there is a lack of demand for the recycled plastic material (Chandrappa, 2007). Another issue with plastic recycling is that there are many different types of plastic and they all have different properties. This means that they have to be sorted and processed separately. Some plastic resins contain toxic and hazardous chemicals and this has led to an increase in costs in the recycling process to ensure that the plastic is recycled in an environmentally safe way (Chandrappa, 2007).

4.1 Technological advancements in plastic recycling machines

A considerable amount of innovation has occurred with respect to plastic recycling machines in recent years. When considering the fact that this technology was in its infancy only twenty years prior, the progress has been remarkable. The largest maker of these plastic bottle shredding devices is a company from the US that has developed a device that separates the fibers from the plastic. These can then be turned into new bottles, thus, in terms of energy this is much more efficient than turning the plastic into downcycled products. Another United States company has designed a machine that uses 3D imaging sensor and X-ray transmission sensor, these are able to identify plastics automatically and sort them accordingly. The machine has been available since 2011 and can process high levels of plastic (up to 6-7 tons per hour). Around the same time in Japan, a very complex machine with multiple sensors was designed. These sensors can detect the type of resin based on the way its molecules scatter infrared lights and sort them into different categories. This has proven to be highly effective but the downfall is that the machines are very costly to produce. An alternative idea has been proposed to create a vending machine that accepts bottles as currency. When the shopper inserts a plastic bottle they are given points to use towards their shopping, coupons for food or discounts on clothing at participating stores. A number of waste plastic bottles are needed to create a large amount of downcycled products and this would often involve shipping the plastics overseas in order to be cost effective. An inventor from New Zealand has created a plastic to oil system which is still in the development stage. The machine will turn plastic back into oil which can then be used for a variety of applications. This is particularly appealing as the oil can be used as fuel which has the potential to be economically and environmentally beneficial.

4.2 Potential for scaling up plastic recycling efforts

Consumer education is also essential to increase the volume and quality of plastics collected. “Many residents are still confused about what types of plastics they can recycle,” says Marge Davis of the Sonoma County Waste Management Agency. “Plastic recycling has evolved since most curbside programs began, and people don’t always realize what is accepted.” This confusion leads to contamination of bales of recyclables with non-recyclable materials, reducing the value of the plastics collected and sometimes making recycling more of a burden than a benefit.

She adds, “Reaching our goal demands hard work on several fronts. Collection is obviously a big issue, in terms of getting the volume and quality of material we need.” Although many American communities have plastic recycling programs, access has not been enough to build a consistent supply of high-quality plastics. That is because only 72 percent of Americans have curbside collection for various recyclables and about 13 percent have access to programs that include plastic bags and film, according to the American Chemistry Council.

“The potential for increasing plastic recycling rates is very high,” says Amanda Dean of the American Plastics Council. “There are a lot of things that need to happen, but our industry is very committed.” According to the U.S. Environmental Protection Agency, concluded efforts to increase plastic recycling would offer a significant benefit. For example, doubling the amount of plastics recycled would reduce the equivalent of greenhouse gases produced by 2.4 million barrels of oil.

4.3 Collaborations and initiatives for a sustainable future

The UK plastics tax is due to come into effect in April 2022, and at this time, ML/FP will also be looking to pave the way in its transition from a plastics manufacturer to a recycling service provider. On the 17th November 2020, ML/FP joined the Made Smarter technology accelerator programme, a partnership between the UK government and industry to boost the productivity and growth of UK manufacturing through the adoption of new digital technologies. This is an exciting opportunity to develop a cost-efficient data-driven waste management system with IoT integration that can demonstrate clear recycling traceability data.

ML/FP has seen a peak in interest in its recycling operations around the news of the UK plastics tax, with companies now looking to divert waste from landfill and to find more sustainable and preferably UK-based recycling solutions with reduced carbon footprints. With investment in new circular economy recycling technologies, ML/FP aims to become a leading force in the recycling of UK waste, which is currently an industry that is often outsourced abroad and can be somewhat unregulated with mixed outcomes on sustainability and benefits to the environment.

The new era of machines has high potential for future developments and will transform ML/FP into a supplier of recycling services not just for its own account but also for companies looking to recycle plastic waste as an additional revenue stream. It may be a few years away, but to put it in context, 20 years ago ML/FP started life as a plastics manufacturer that outsourced recycling, and using this business model, it is now on the brink of creating a recycling service both interior and exterior and for multiple waste streams that can be replicated throughout UK industry with a huge culture change in how waste is handled and disposed of. This represents a big step towards sustainability and a circular economy, and the rationalization for this evolution has been written into the development roadmap of ML/FP.